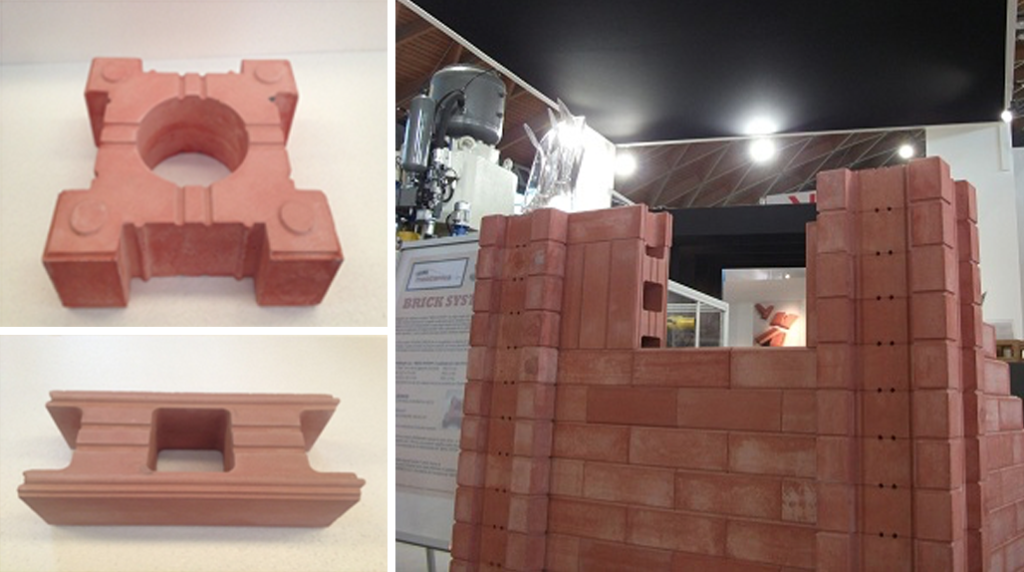

The project of joint brick called “Brick System” begins in the 60th year. In those years a company from Emilia-Romagna tested some structures that resulted positive. The project was gave up because the cost of production was very high cause they had not a specific technology to build a brick with perfect geometric form ( fist bricks had to be single grinded).

Since some years Tecnomeccanica projected a system for the pressed brickworks, that permit to produce brickworks with geometric forms hundredth. This technology permit to realize joint pieces without work problems.

Benefits

Less humidity

The finished product is obtained by pressing, a process that allows easy drying. Thanks to this procedure, the product will have a humidity of 5-8%, instead of 20%.

Greater accuracy

LThe lower water quantity used in the dry process, allows a remarkable reduction of the shrinkage during drying process, with a maximum value of 1.5% against the 5-8% of the extrusion process.

Greater versatility

You can use all the ranges of clays, shale clay and clays with high sand content, without any need of plasticity and quality required in extrusion process.

Features

The structure realized with Brick System is made with different pieces:

• square piece “Jolly” with 4 hold sides 33 x 33 x 6/8 – weight 4,5 Kg

• rectangular piece 12,5 x 33 x 6/8 – weight 3,0 Kg

• rectangular piece 12,5 x 15,5 x 6/8 – weight 1,5 Kg

• closed plate to insert in the free side of square piece.

Technical features:

• pressed product with grinded dry clay

• damp 7-8%

• specific pressure 250 Kg/cm2

• superior compression resistance 450 kg/cm²

The finished product is certified for the construction of supporting structure.When the product comes out from the press it can be directly loads on the kiln carriage, because, it is a pressed product with a max damp 7-8 % and it has a specific very high pressure that made it support. The productivity of the press for the production of Brick System s about 8-10 ton/h.

The final test of this product are made by research laboratory Tecnomeccanica in Sassuolo, while the industrial test are made in Colombia with the press Brick 1000 in the company LADRIGRES S.A.S. that holds the exclusive right of “Brick System” for the Colombian trade.

Do you want to find out more? Discover our BRICK 600 and BRICK 1000 L presses that use this system.