Our services

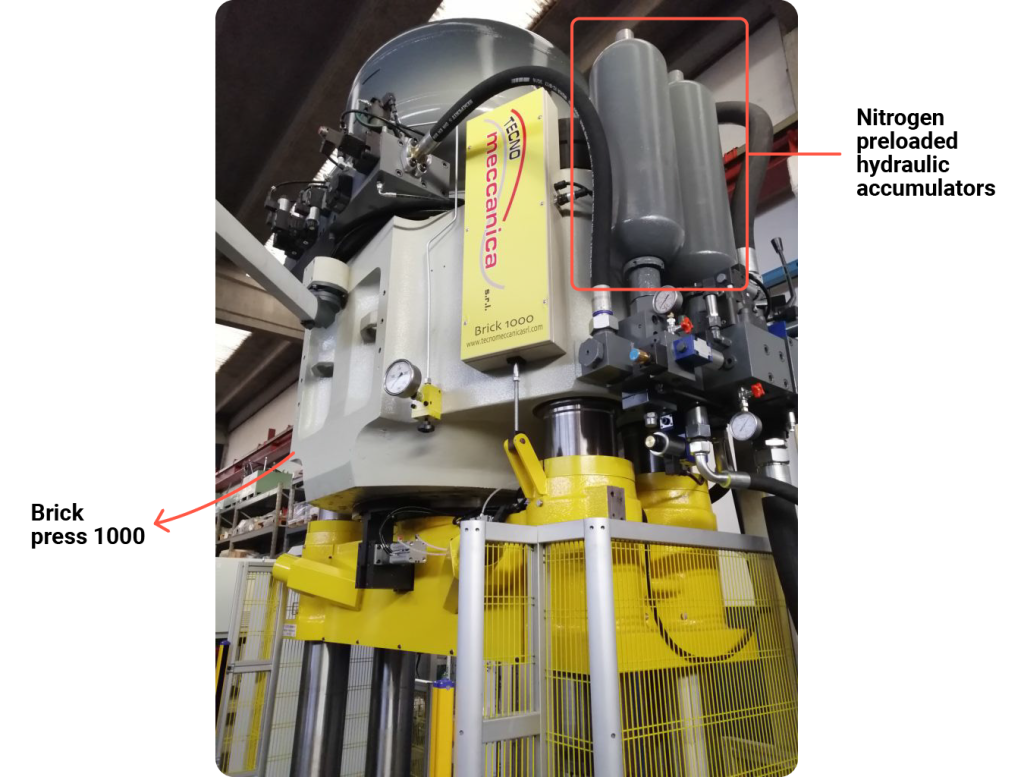

Modern hydraulic presses for the production of tiles and pressed bricks, in order to function correctly and maintain constant pressure during the production cycle, require hydraulic pressure accumulators preloaded with gaseous nitrogen.

The crescent requirement of quality in the trade of ceramic products and pressed brickwork, has oriented our company towards the construction of a machine tool to numerical control of highest precisionto apply to press to rectify he support plan mould.

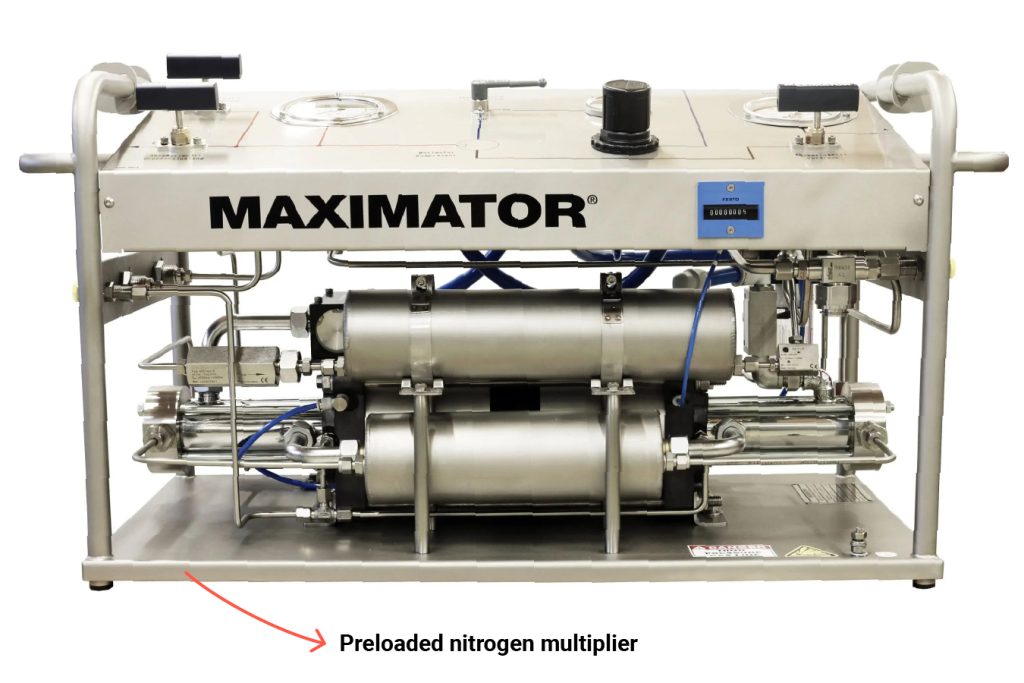

Accumulators pre-charge

Tecnomeccanica provides the hydraulic accumulator pre-charge service directly at the production plants with the aid of a state-of-the-art pressure multiplier that allows you to reach the required nitrogen pressure.

Plans rectification

The crescent requirement of quality in the trade of ceramic products and pressed brickwork, has oriented our company towards the construction of a machine tool to numerical control of highest precision to apply to press to rectify he support plan mould.

The support called Bench Press , after work years it has an usury and in same cases it deformet itself also about some millimetre. This process involve the alteration of the mould and reduces the duation of itself.

The rectification machine can be transportated in the company in there where are installed the press to re-establish; it is fixed to the crossbeam and with special balance system it adjust itself, stopped the balance and adjust phase the machine re-establish support plane in automatic.

When the work is finished the tolerance of a support plane with light mm 1750 and width mm 1250 doesn’t over 3 hundredth millimetre.

Items used for the construction of the rectification machine are all of last generation, guides and towing screws, firma Bosch and Rexroth, are the same used for the construction of tools machines. The movements are controlled by servo-motors, managed by PLC that is porgrammed with a control system of hundredth precision shaft.

Features

The machine can be installed in the press that have light between columns from 1100 mm to 1750 mm.

Work field

Shaft X mm 1750

Shaft J mm 1250

Shaft Z mm 20

Spindle speed RPN : 10/1207 run/min

Feed: within 6000 mm/min

Head contains tool that run on the spheres circle Timken

Power motor: 1.6 Kw